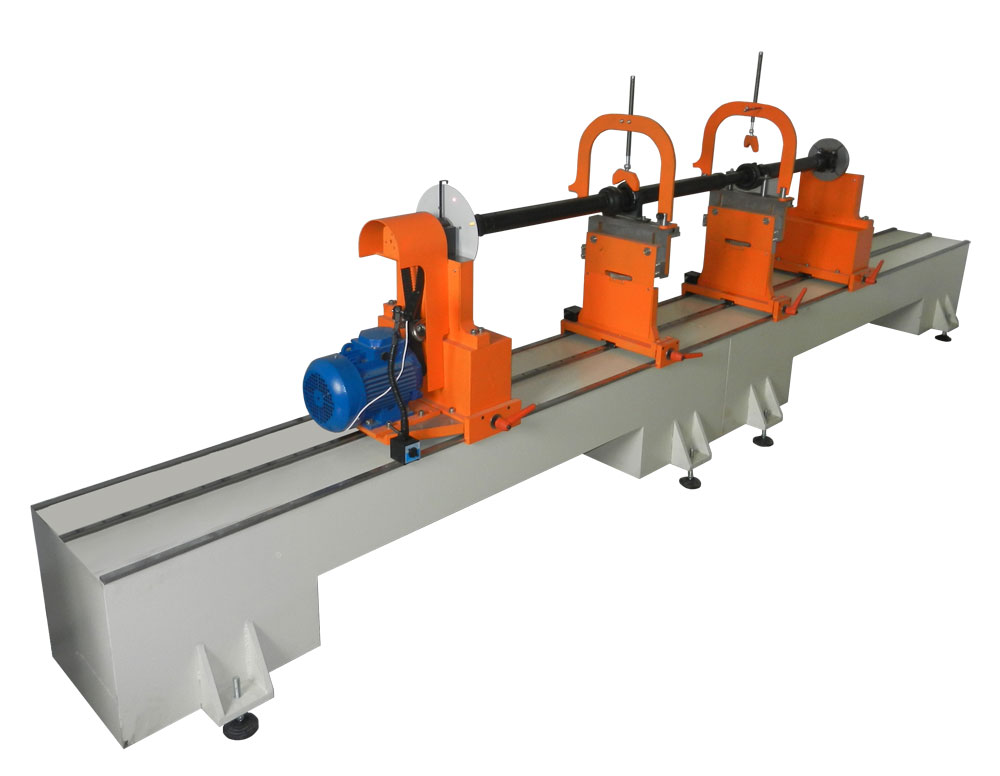

It’s no secret that most of these balancing equipment and works with joints, length 2650-2900 mm, which greatly reduces the scope of their application. TB cardan 4000, allows you to balance not only the shafts of passenger cars, pick-UPS, short of vans and light trucks, but also the joints for commercial vehicles with extended wheelbase, special equipment, etc., until railway transport.

Also, the machine can be modified for balancing crankshafts.

√ Corazonada measurement system imbalance with a hard suspension

Low, doresearch speeds, increases safety and reduces the time of balancing.

√ High-precision system linear motion

The movement supports the linear movement is carried out with minimal effort, one finger allows you to reconfigure the machine for another size of the rotor almost instantly.

√ High-quality components

Components manufactured in Europe (handles, rollers, pulleys, etc.) significantly increase accuracy, reliability and service life

√ Improved system of fastening of a shaft

Allows you to use a minimum of expensive adapters and flanges.

√ Machine bed made of polymer concrete with a vibration-absorbing coating

Reduces the dependence of the measurement from external vibrations, and allows the phase balance near other powered industrial equipment.

√ Installation on antivibration mountings

The machine requires no special Foundation (set of 4 anti-vibration mount), and can be easily moved using manual hoists.

* Output of measurement results on PC

Ease of use, versatility, lower cost machine.

TB Card 4000

Machine for balancing propeller shafts with length up to 4200 mm, weighing up to 400 kg.

The model has 4 racks and allows balancing at once in 4 planes of correction. Since the machine was specifically designed for repair providers, special attention was paid to the possibility of balancing shafts widest range of models present in the market.