√ Corazonada measurement system imbalance

Low, doresearch speeds, increases safety and reduces the time of balancing.

√ Hard suspension

Enables correction masses to be balanced without removing product from the machine.

√ High-precision system linear motion

The movement supports the linear movement is carried out with minimal effort, one finger allows you to reconfigure the machine for another size of the rotor almost instantly.

√ High-quality components

Components manufactured in Europe (handles, rollers, pulleys, etc.) significantly increase accuracy, reliability and service life of the machine.

√ Machine bed made of polymer concrete with a vibration-absorbing coating

Reduces the dependence of the measurement from external vibrations, and allows the phase balance near other powered industrial equipment.

√ Installation on antivibration mountings

The machine requires no special Foundation (set of 4 anti-vibration mount), and can be easily moved using manual hoists.

* Output of measurement results on PC

Ease of use, versatility, lower cost machine.

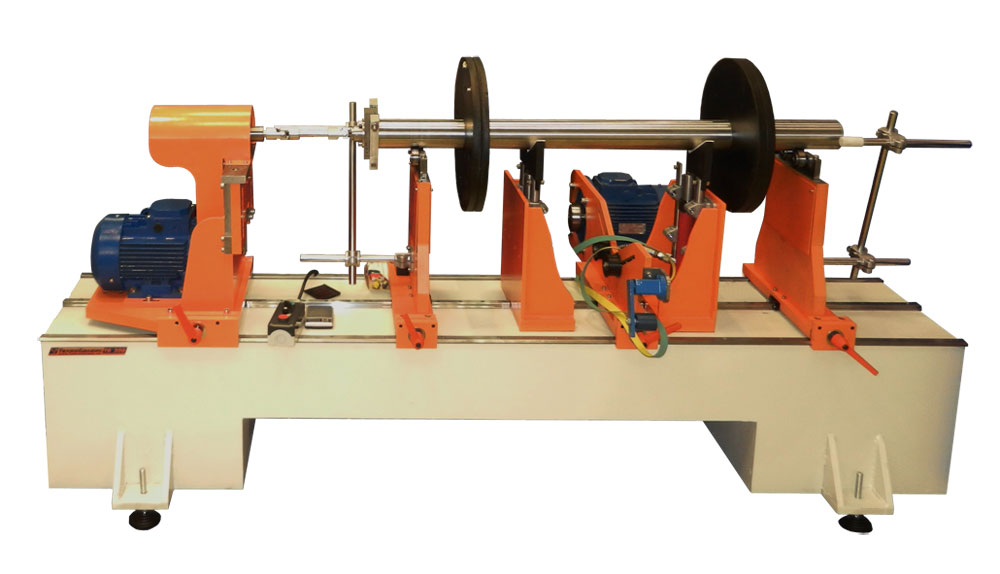

TB 300 Mod 2300

A modified version of the machine ТБ300 with extended frame and axial drive allows to balance rotors weighing up to 300 kg and with a maximum distance between the supporting necks of the balanced rotor is 2000 mm.

Axial drive of the original design, allows the use of fewer adapters, allows for precise positioning of the rotor to be balanced. Precision balancing of 0.5 g*mm/kg., if necessary, the machine is produced in versions with a precision balance 0.1 g*mm/kg.